E-mail: [email protected] Whatsapp: +8613647327093 Tel: +86-731-8403-0163

E-mail: [email protected] Whatsapp: +8613647327093 Tel: +86-731-8403-0163

Hydraulic Pile Breaker

Brand: Unimate

Models: SP800

Warranty: 1 Year

Application: Breaking down the concrete pile header for foundation pile

You May Also Like...

For pile foundation, chopping concrete piles can be challenging, especially with strict site norms. And the traditional manual way is no longer applicable due to its inefficiency and a host of other potential hazards. You will need a revolutionary way to dismantle pile concrete to cut-off level.

Unimate Pile Breaker is an efficient, economical, clean and advanced system for cutting concrete outcrops and foundation piles.

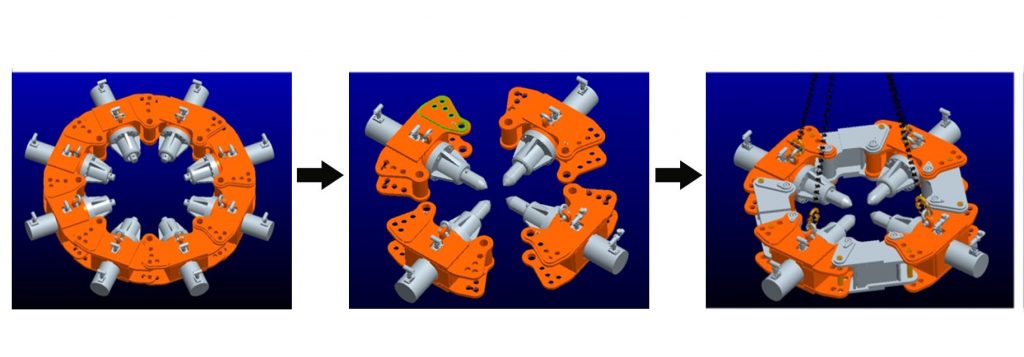

The modular design makes the pile breaker extremely easy to crush concrete piles of different diameter at the jobsite. Additionally, each module contains a separate cylinder and brazing rod system. With the help of hydraulic pressure, the oil cylinder drives the brazing rod to squeeze the pile.

Thanks to this way of working, no cracks and damage will be caused to the pile and reinforcement underground. Also, thanks to the independent modular structure, air and noise pollution in construction sites will be reduced significantly.

When it comes to the efficiency of our pile crusher, we have the detailed data to back it up. The traditional way of crushing normally takes one day for one pile. However, the Unimate pile breaker is more than 10 times faster than the traditional breaking process due to its automatic process.

SP800 Convert To A Square Pile Crusher

| SP800 (a group of 16 modules) | |

| Model | Sp800 |

| Max. cutting diameter (mm) | Φ450﹣Φ2500 |

| Max. hydraulic cylinder pressure force (Mpa) | 24.3 |

| Cutting capacity (pcs/hour) | 200-100/8 |

| Max. height of a single crush (mm) | ≤300 |

| Excavator tonnage (t) | ≥35 |

| Single module weight (kg) | 381 |

| Single module dimension (L*W*H) | 908×780×400 |

| Operation dimension | Φ3200×3000 |

| Total weight (t) | 6.4 |

| SP800 parameters | ||||||||||

| Module Qty | 6 | 7 | 8 | 9 | 10 | 11 | 13 | 14 | 15 | 16 |

| Cutting range (mm) | 450-600 | 650-800 | 850-1000 | 950-1200 | 1150-1400 | 1350-1600 | 1650-1800 | 1850-2100 | 2050-2300 | 2250-2500 |

| Excavator tonnage (t) | 20 | 22 | 26 | 27 | 30 | 32 | 35 | 35 | 40 | 46 |

| Total weight (kg) | 2400 | 2800 | 3200 | 3600 | 4000 | 4400 | 5200 | 5600 | 6000 | 6400 |

| Height of a single crush (mm) | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

Download

Contact Us